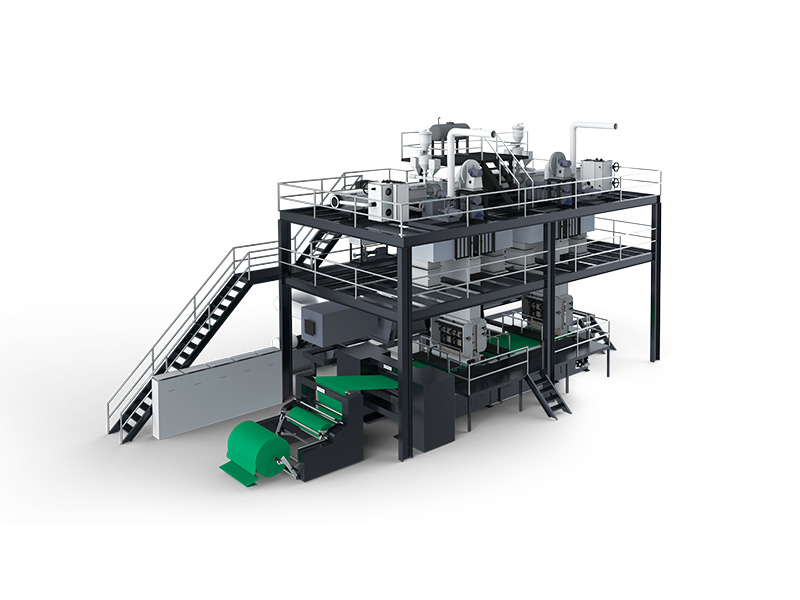

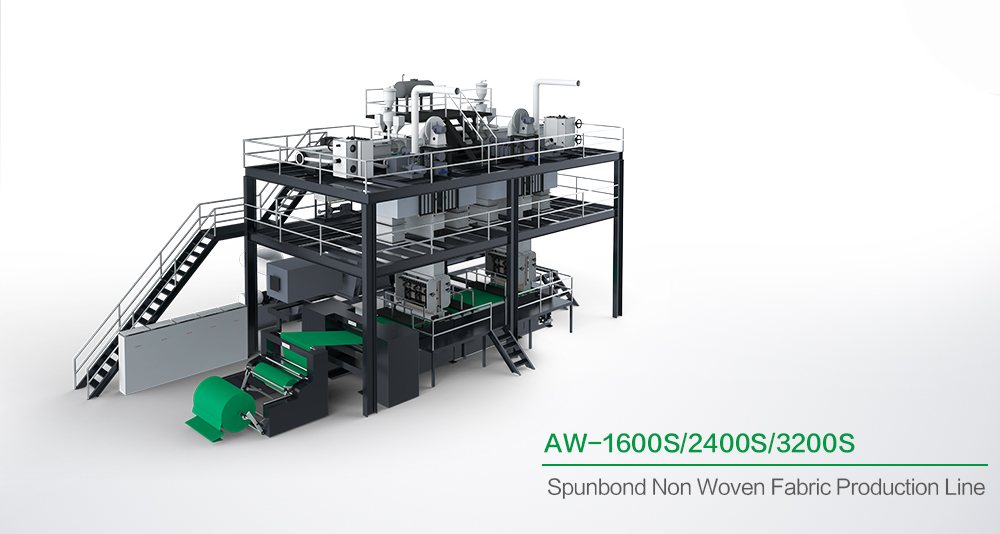

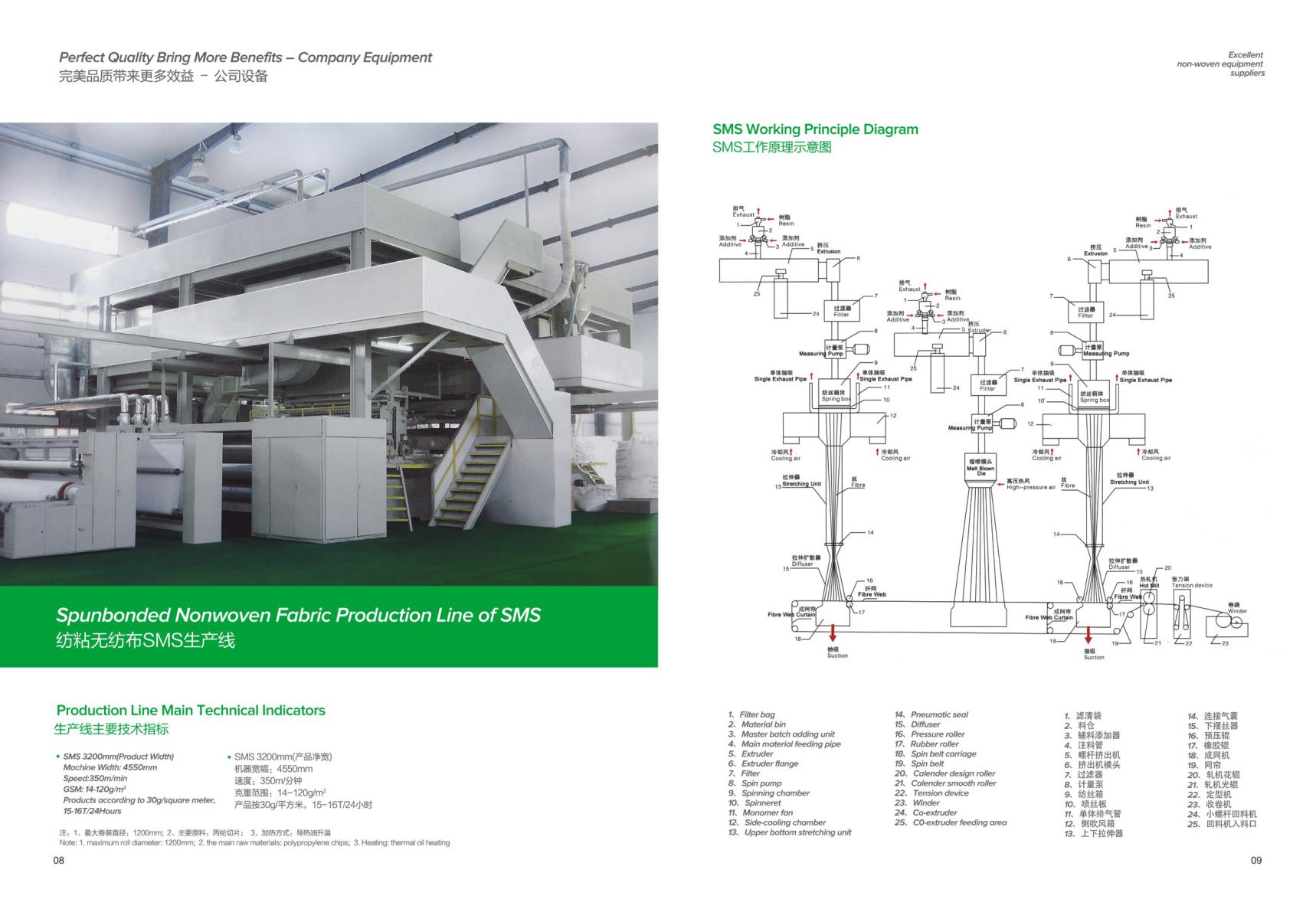

AW-1600S/2400S/3200S Single S Spunbond Non Woven Fabric Making Machine

This machine is suitable for PP spunbond non woven fabric making. It used PP chips as raw materials input, undergoes the process of extrusion, spinning, quenching, closure air stretching, web formation, calendaring, winding and cutting as per requirements and then packed for storage and delivery.

|

ITEM |

EFFECTIVE WIDTH |

GSM |

ANNUAL OUTPUT |

EMBOSSING PATTERN |

|

S |

1600MM |

8-200 |

1500T |

Diamond, oval, cross and line |

|

S |

2400MM |

8-200 |

2400T |

Diamond, oval, cross and line |

|

S |

3200MM |

8-200 |

3000T |

Diamond, oval, cross and line |

|

SS |

1600MM |

10-200 |

2500T |

Diamond, oval, cross and line |

|

SS |

2400MM |

10-200 |

3300T |

Diamond, oval, cross and line |

|

SS |

3200MM |

10-200 |

5000T |

Diamond, oval, cross and line |

|

SMS |

1600MM |

15-200 |

2750T |

Diamond and oval |

|

SMS |

2400MM |

15-200 |

3630T |

Diamond and oval |

|

SMS |

3200MM |

15-200 |

5500T |

Diamond and oval |

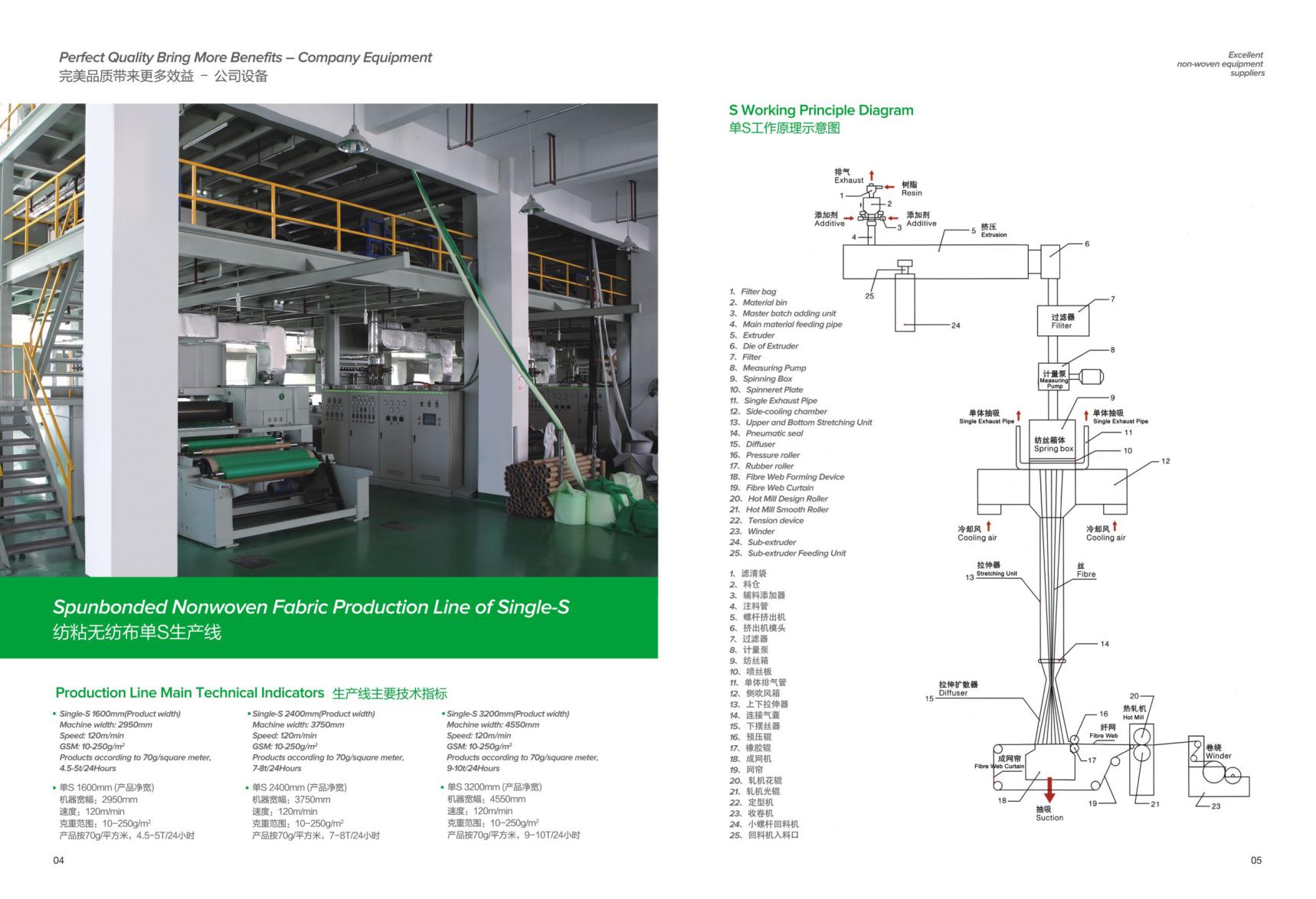

S Working principle diagram

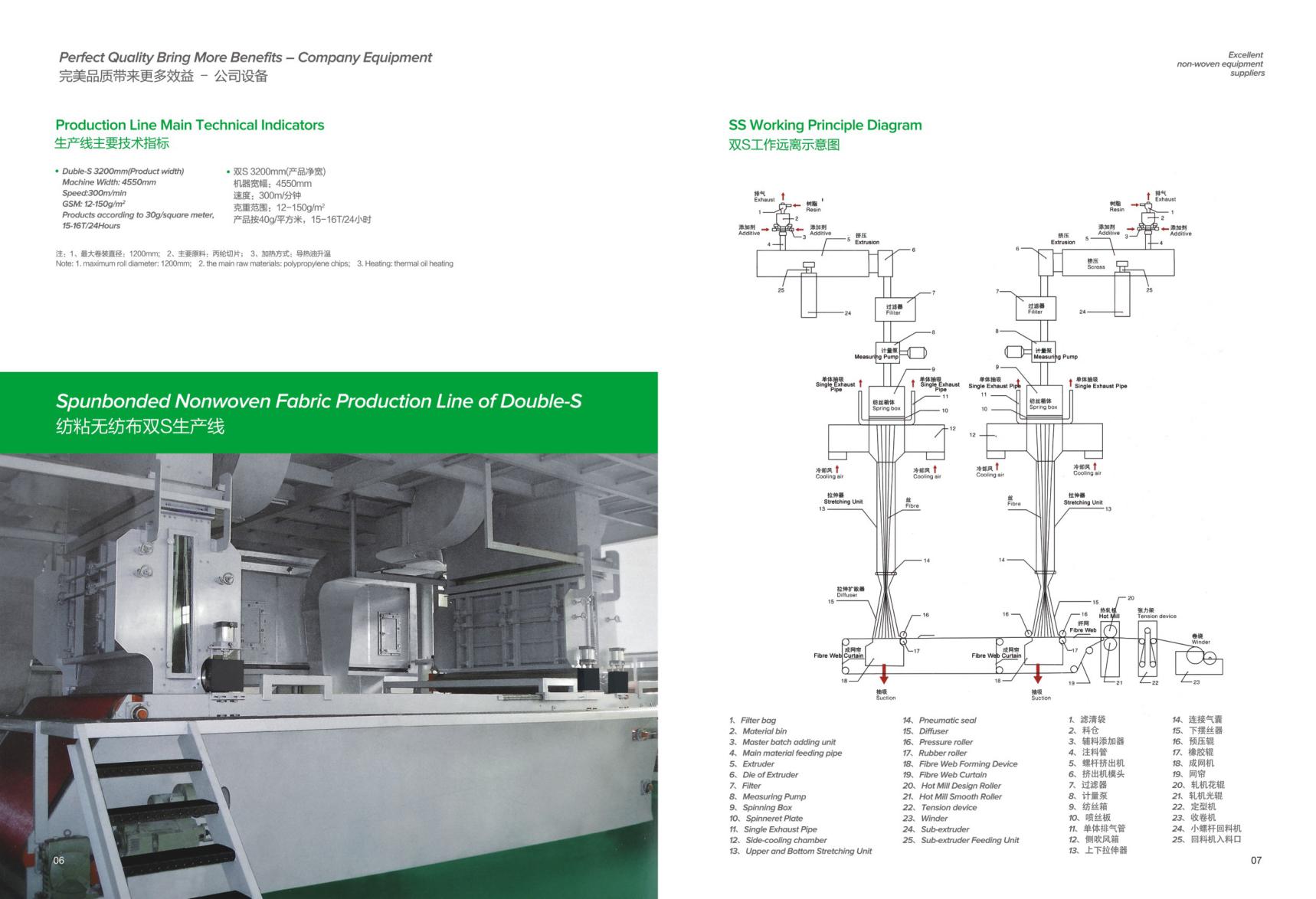

SS Working principle diagram

SMS Working principle diagram

NONWOVENS APPLICATIONS

Allwell Nonwoven lines are designed and manufactured in accordance with individual customer requirements. Their possible area of application is correspondingly wide. Such as :

PACKAGE - Shopping bag, Rice

Packaging, Clothes packaging, etc.

HYGIENE - Baby and adult diapers, Female hygiene, etc.

MEDICAL - Surgeon's masks, Disposable garments, etc.

FURNITURE - Beds Cover, Seatings Cover, etc.

TECHNICAL - Geotextiles, Agriculture, etc.

FILTRATION - Air, Gas, Liquids, etc.

|

(1)Online cutting, automatic fabric rolls changing. The maximum speed is 150m/min (2)Tension is uniform, winding is neat. The largest diameter of fabric is 1.5m (3)Counting meters synchronously and accurately. The maximum number is 9999m. (4)Allwell Winder can run separately(single action status) |

|

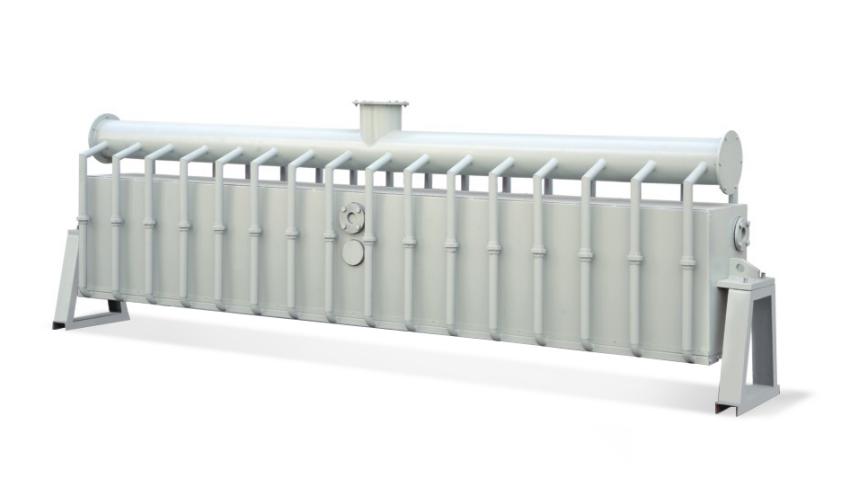

Hot mill (1)Temperature is uniform, difference in temperature≤2℃ (2)Pressure is uniform, fabric is even. (3)Speed is even, which is (10-150)m/min (4)Easy operation and maintenance. |

|

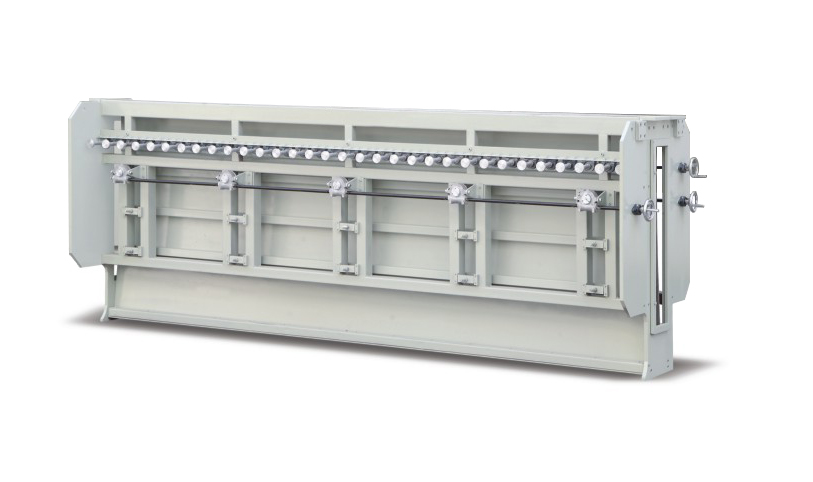

Stretching Unit Features: The stretching unit is slit type. 1. High effeciency of stretching, low power consumption |

|

Thermal Oil HeatingSystem

(1)The head of

screw is heated by thermal oil heating system.

|

|

Spinning Box andSpinning Components Spinning components include filter, distributing plate, sealing strip, etc. Allwell spinning box symmetrically by pressure to spinning components and heat and retain heat for melted material as the last step.

|

|

Electrical ControlSystem According to the characteristics of producing spunbonded non woven fabric, Allwell adopts external advanced electric control manner to operate the extruder by manual and automatic way.

|

|

Special data would be supply after confirm your order.

|

|

|

Package

|

As per export standard, they will also be treated before delivery against damage and rusting.

|

|

Container |

1.6S ----4x40'HQ + 1x20'GP; 1.6SS---9x40'HQ + 1x20'GP;

2.4S-----5x40'HQ; |

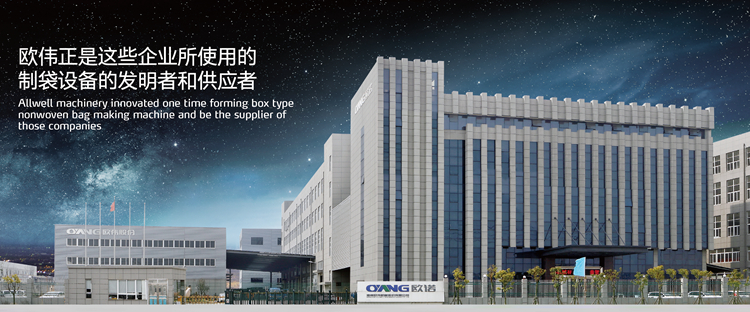

Allwell Machinery,

as a professional manufacturer of spunbonded PP non woven fabric line, non

woven bag making machine, non woven printing machine, soft handle sealing

machine and relevant equipment, has an

area of 13,000 square meters

and 130 on-the-job employees.

We start from a smart factory since 2006. We keep innovating and upgrading

equipment to make non woven bag more attractive and durables. 2012-2013, we

innovated the first set of one time forming laminated non woven box bag making

machine all of the world and get successfully market. The products and services

now cover more than 80 countries.

Today, we are adhearing energy saving, efficient, environmental idea to be the

leader of non woven bag making industry. We have a great dream and responsibility

to provide solution for the intelligent bag making industry.

Allwell have gained

the certificate of ISO9001 quality management system with all products gained

the European CE.

Our R&D Team merges the advanced philosophy to practice and succeeds in

applying to the related products. The excellent quality and performance of our

product originatedfrom our

long-term and continuous test and improvement. 2012-2013, we setup a new

project of one time forming

non woven box bag making machine. We succeed developed this machine

- Leader Machine and

get the invention patents as shown above.

2015, we succeed build a new factory and 2016 we import 5 set CNC 5 sides work coordinate machining, 24 hours processing to guarantee the precision of the machine. All our products are better than the relevant industry standards.

Pre-Sales One-stop Service

* Inquiry and consulting support

* Latest industry trends

* More fit bag making solution

* Sample testing support

* View our Factory

* Suggest layout support

After-Sales Service

* One year warranty

* Machine test video before delivery

* English Manual, Electric Diagram

* Training how to install the machine, training how to use the machine

* Engineers available to service machinery overseas

- Conseiller principal en fabrication de sacs non tissés

- Nom du contact: Emy Tung

- Email: inquiry@allwell-group.com

- Téléphone portable: +8613567711278

- WeChat: 13567711278

- WhatsApp: +8613567711278