Product Application

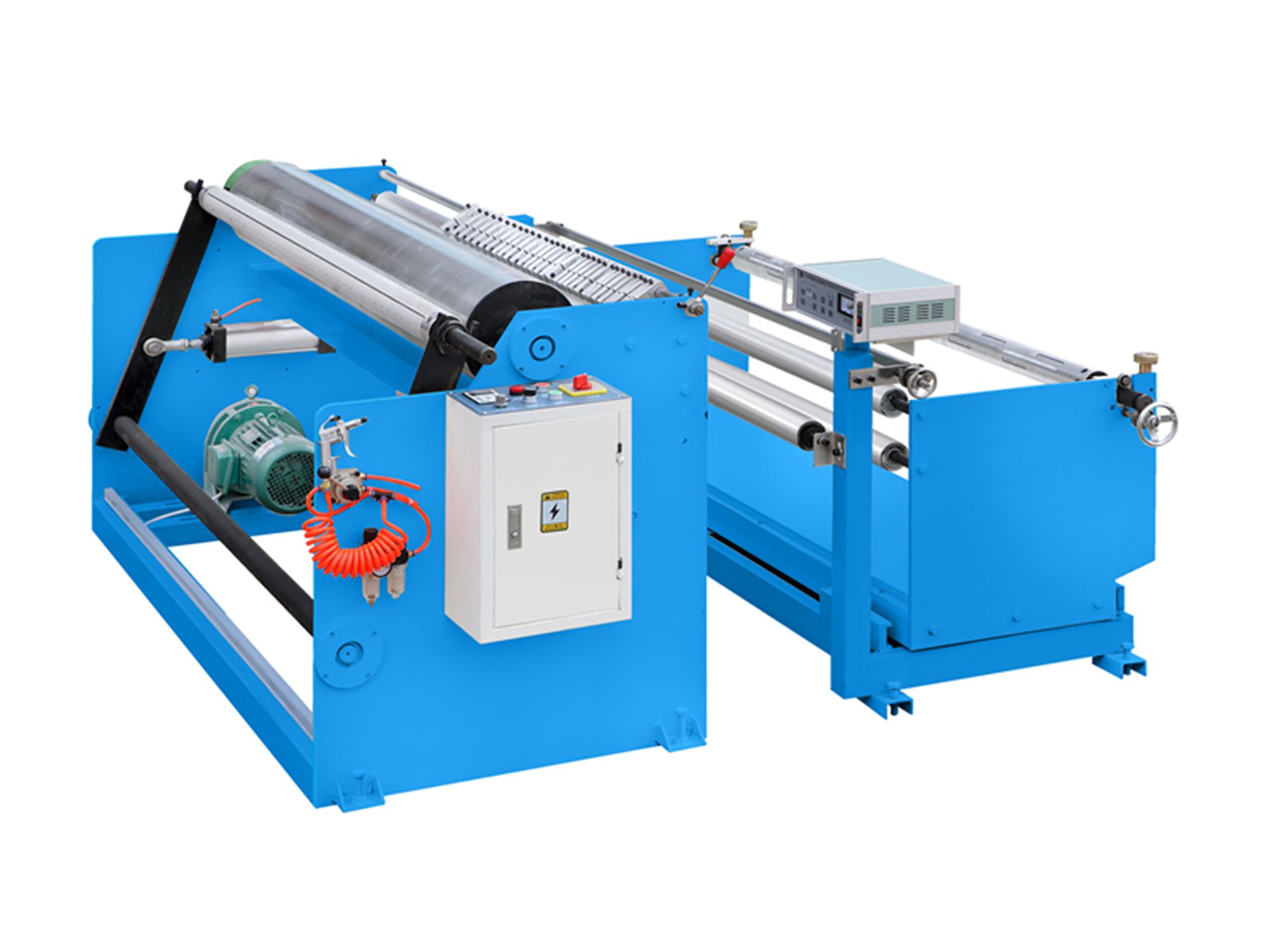

ONL-XE1800 Non Woven Slitting Machine is special for non woven fabric slitting. Also can slitting BOPP,PET,CPP,PVC and other plastic films.

|

Main Technical Variables |

||

|

Type |

ONL-XE1800 |

|

|

Slitting width |

25-1800mm |

More wider or more narrow can |

|

Slitting speed |

30-80m/min |

|

|

Power supply |

220v 50Hz |

|

|

Total power |

3 kw |

|

|

Overall size |

2400x1800x950mm |

|

Features

1. Plat steel welding, firmly and balanced, more stable in the

high-speed operation

2. chromium-plated steel pipe dynamic balance processing

3. Feeding with 3 inch air shaft, maximum feeding diameter is 1000mm, with magnetic powder tension controller and edge

automatically align device.

4. rewinding with 3 inch air shaft and magnetic powder controller, easy to

operate, maximum rewinding diameter is 1000mm;rewinding aesthetic and neatly.

5. Cutter can use special blades or flat knife (cutter blades), 18mm-3200mm

adjustable.

6. Electric speed control system with manual adjustment, convenient and simple

to operate.

7. Importing precise ball screw and slides, paralleled promoting the cutting

width, importing AC motor step-less adjustment system to adjust and control the

cutting speed, high-precise cutting, and the accuracy can be controlled within

0.1mm.

8. Standard configuration

deviation-checking equipment system to further ensure the cutting precision.

9. Several kinds of cutting width and

number of load settings, and with manual/automatic conversion function, making

the operation more simple and convenient;

10. High speed feeding design, reducing

the labor effectively and increasing the production efficiency, automatic counting device, clear at a glance.

|

|

|

Rewinding Part |

Feeding Part |

|

|

|

|

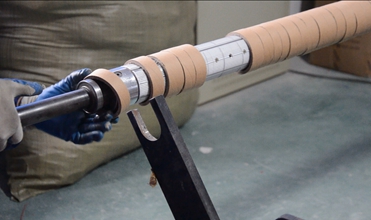

Cutting Paper Tube |

Tube Put On Air Shaft |

|

|

|

|

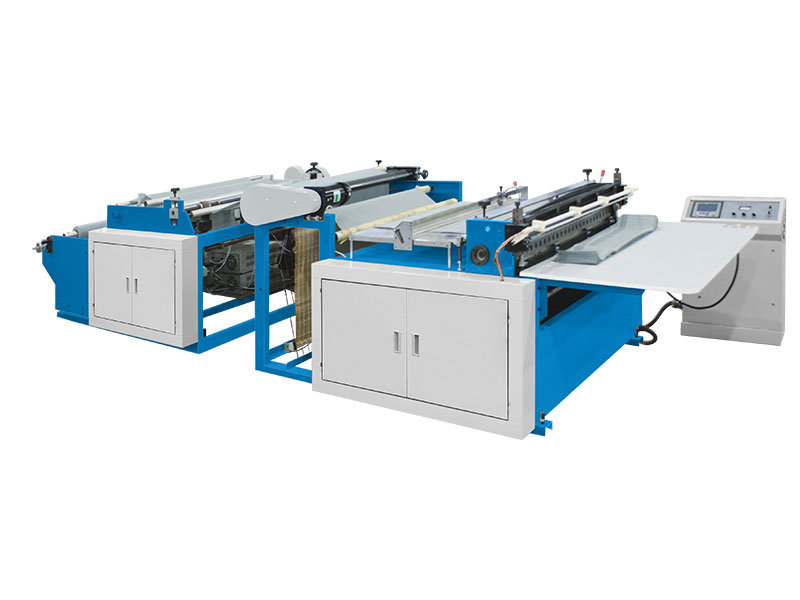

Adjust Knives Distance |

Adjust Electric Eye Site |

|

|

|

|

Adjust Magnetic Tension Device |

Adjust Speed, Start Slitting |

|

The following is OUR load container info for ONL-XE1800 Slitting Machine Feeding Part. Special data would be supply after confirm your order.

|

|

|

Weight

|

250KG

|

|

Packaging Details |

1.no package

2.plastic film with pearl cotton 3.wooden pallet as your request

|

|

Slitting Machine Rewinding Part Delivery

|

|

|

Weight

|

400KG

|

|

Packaging Details

|

1.no package

|

|

Pipe cutting machine Delivery |

|

|

Weight

|

100KG

|

|

Packaging |

Standard Package for the circular cutter

|

Allwell Machinery, as a professional manufacturer of spunbonded PP non woven fabric line, non woven bag making machine, non woven printing machine, soft handle sealing machine and relevantequipment, has an area of 13,000 square meters and 130 on-the-job employees.

We start from a smart factory since 2006. We keep innovating and upgrading equipment to make non woven bag more attractive and durables. 2012-2013, we innovated the first set of one time forming laminated non woven box bag making machine all of the world and get successfully market. The products and services now cover more than 80 countries.

Today, we are adhearing energy saving, efficient, environmental idea to be the leader of non woven bag making industry. We have a great dream and responsibility to provide solution for the intelligent bag making industry.

Allwell have gained the certificate of ISO9001 quality management system with all products gained the European CE.

Our R&D Team merges the advanced philosophy to practice and succeeds in applying to the related products. The excellent quality and performance of our product originatedfrom our long-term and continuous test and improvement. 2012-2013, we setup a new project of one time forming non woven box bag making machine. We succeed developed this machine - Leader Machine and get the invention patents as shown above.

2015, we succeed build a new factory and 2016 we import 5 set CNC 5 sides work coordinate machining, 24 hours processing to guarantee the precision of the machine. All our products are better than therelevant industry standards.

|

|

Pre-Sales One-stop Service

* Inquiry and consulting support |

After-Sales Service

* One year warranty |

- Bolso sénior no tejido haciendo consejero

- Nombre de contacto: Emy Tung

- Email: inquiry@allwell-group.com

- Teléfono móvil: +8613567711278

- WeChat: 13567711278

- WhatsApp: +8613567711278