New Box Bag Making Solution

Solution Introduction:

|

Machine List |

Selected |

|

M1. Non Woven Fabric Making Machine USAGE: For support PP spun bonded non woven. |

|

|

M2. Non Woven Slitting Machine USAGE: For support suitable width non woven roller. |

|

|

M3. Rotogravure Printing Machine USAGE: For printing BOPP film. |

|

|

M4. Non Woven Coating and Laminated Machine USAGE: For material lamination, laminating non woven fabric and BOPP film. |

|

|

M5. Leader-11 One Time Forming Non Woven Box Bag Making Machine USAGE: For bag making automatically, folding and packaging finished bag automatically. |

|

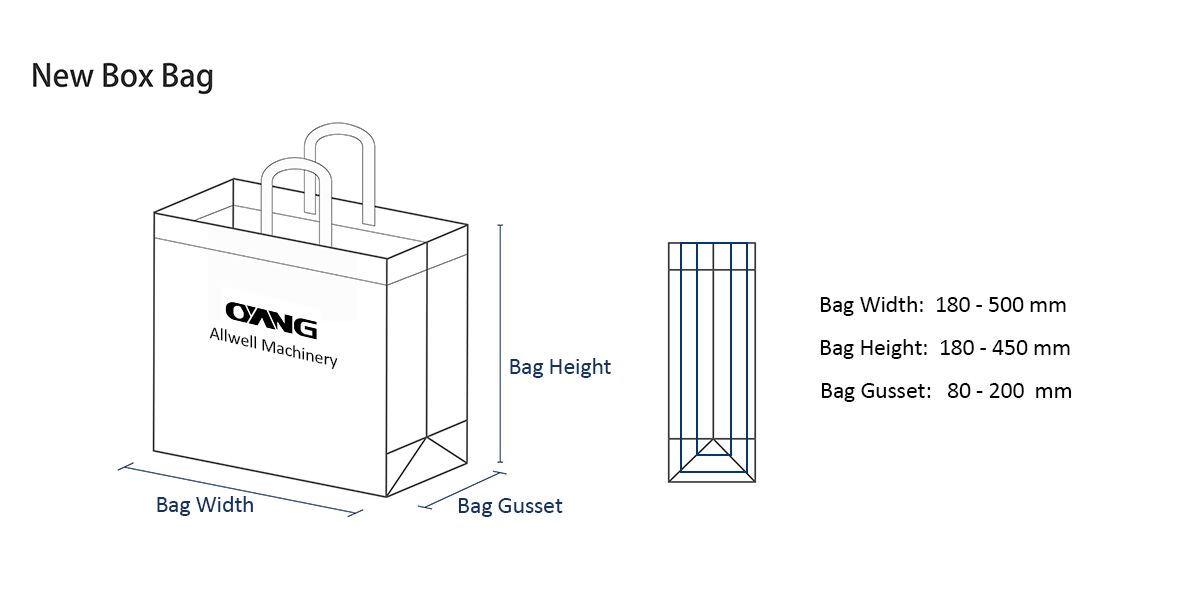

Bag Specification:

This solution can make laminated non woven box bag, non-laminated non woven box bag with different printing effect. Such as screen printing, flexo printing, offset printing, etc.

Bag size depend on the M5. Leader machine. The max height is the half of bag gusset plus 350mm. The standard bag size as follow:

Note: if your bag size is out of the standard range, you can choose Individual Solution - see

Space Requirement

General: 45*30*10 m

As a new business, the majority of our customers would choose this solution except M1. Non Woven Fabric Making Machine to start first. Also for the long term, most people would think of M1. Nonwoven Machine according to their actually necessary and monthly bag capacity.

Allwell team would supply you the special space after confirm your final machine item.

Cost Analysis

Allwell Sales Team would give you a more clear analysis according to your requirement after we build a favorable communication. As different country, the cost of electric and water, labor and manage cost are total different. We would initially provide one general local date from our large customer group to give you more confidence about this investment.

Of course, we also provide the cost calculation of bag. Bag type, Material amount, Material wastage, Material price, Gramme , Printing cost, Lamination cost, Labor and electric, Profit rate, etc.