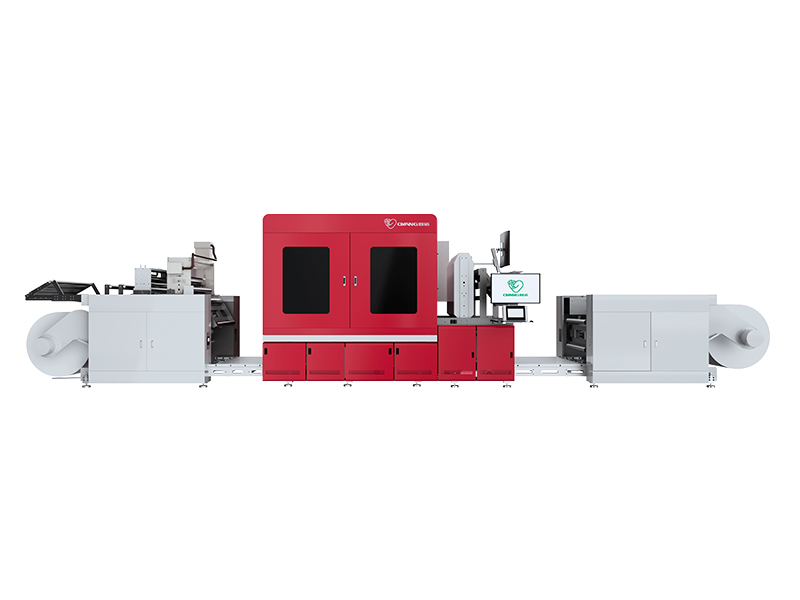

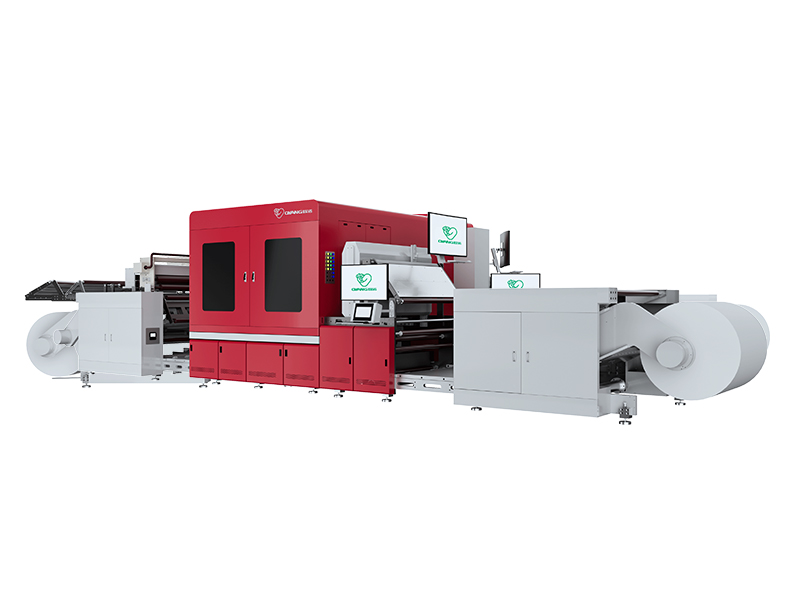

Product Application

It can be widely used in Paper Carboard Printing,Corrugated Digital Printing.

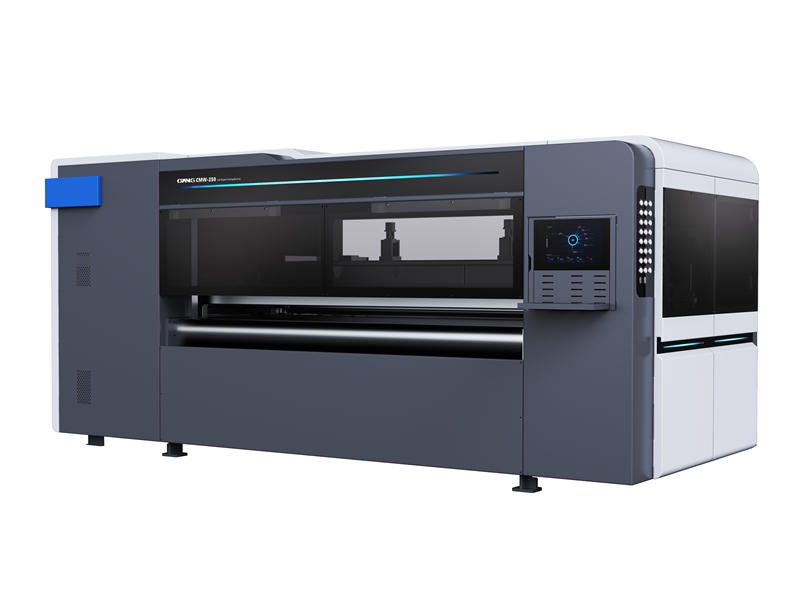

Main Technical Variables

喷墨印刷功能Inkjet printing function

|

喷墨分辨率 Printing resolution |

360*600DPI |

720*600DPI |

720*1200DPI |

|

8喷头印刷速度 8 Nozzle print speed(CMW250e8) |

900㎡/h |

450㎡/h |

230㎡/h |

|

13喷头印刷速度 13 Nozzle print speed(CMW250e13) |

1560㎡/h |

900 ㎡/h |

450㎡/h |

|

16喷头印刷速度 (CMW250e16) |

1930㎡/h |

900㎡/h |

500㎡/h |

|

喷头类型 Nozzle Type |

日本原装EPSON压电式喷头 EPSON Piezoelectric Nozzle (Original from Japan) |

||

|

喷头数量 No. Of Nozzle |

8/13/16 pcs |

||

|

喷头介质距离 Nozzle medium distance |

2MM-4MM |

||

|

最大印刷幅面 Max. print width |

2500*2000MM |

||

|

喷头打印宽度 Nozzle print width |

8喷头:267mm 8 Nozzles |

13喷头:434mm 13 Nozzles |

16喷头:534mm 16 Nozzles |

|

干燥速度 Dry speed |

瓦楞纸板即印即干 Dries instantly on corrugated paper |

||

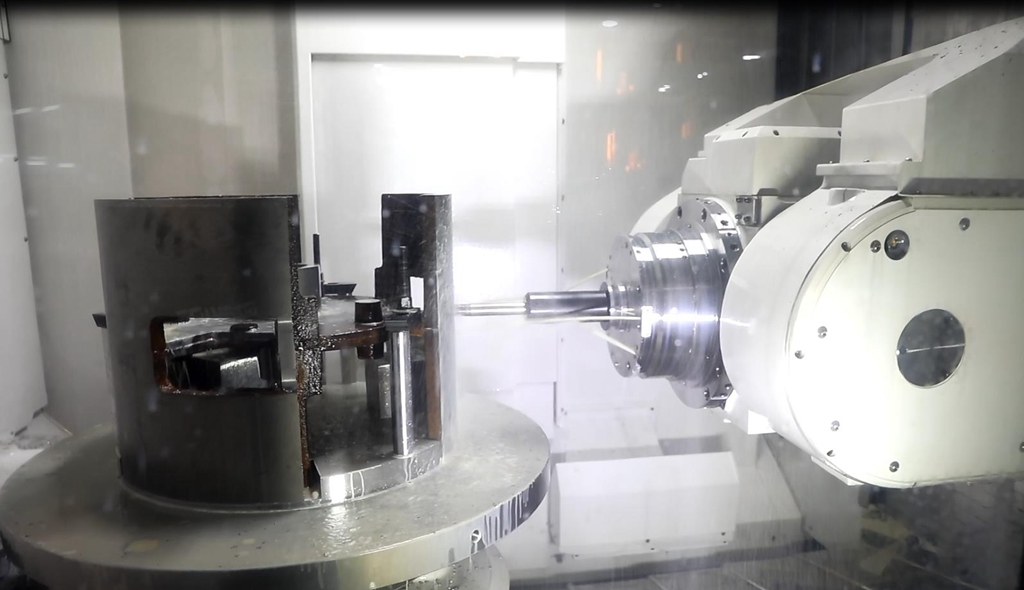

Main wallboard: The raw material is nodular cast iron, which made by pouring molten iron. More force and wear resistance, high strength, high toughness, stable running and machine life extended by up to 80 %.

Big hub: Integral casting , 5-axis machining, perfectly curved surface, finished in 10 hours continually work, minimize fitting errors.

Former support: The former support is to held the big hub,so it should be strong enough for high speed and long time running.

Developing fast and covering an area of 130,000㎡。

MAZAK HCN6800L FLEXIBLE PRODUCTION LINE (6 SETS)

MAZAK HCN6000L FLEXIBLE PRODUCTION LINE( 6 SETS)

Mazak Horizontal Machining Center. The maximum capacity of the tool magazine is 330 tools, which can meet the requirements of workpiece diversification and unmanned production.

MAZAK VCN700DL ( 1SET)

Mazak vertical machining center. Agile spindle acceleration and deceleration, high-speed axis feed, and efficient tool exchange effectively shorten the processing time.

MAZAK QTC200MYL ( 2SETS)

MAZAK QTC300MYL ( 2SETS)

Third, Mazak CNC lathe. Using the latest SMOOTH G system, it can be widely used in aerospace, instrumentation and other industries. High-efficiency machining requirements for small precision parts.

Mazak i-630v/6 ( 1SET)

Fourth, Mazak 5-axis simultaneous vertical machining center. The equipment is equipped with a swing spindle and a rotary table, which can perform 5-axis simultaneous machining of complex surfaces.

Okuma MCR-A5II25 (4SETS)

Fifth, OKUMA-MCR gantry type 5-sided machining center. Equipped with various extended processing systems to complete 5-sided, curved and other three-dimensional processing, the roughing and finishing of almost all processes can be completed in one clamping.

- Packing project conserlor

- Contact Name: Emy Tung

- E-mail: inquiry@allwell-group.com

- Mobile Phone: +8613567711278

- WeChat: 13567711278

- WhatsApp: +8613567711278

-161023.jpg)