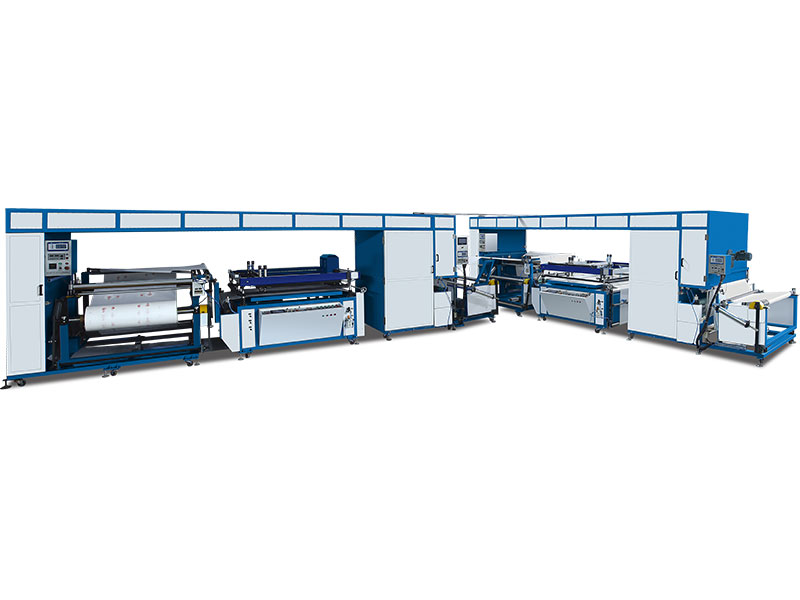

Product Description

With balanced pressure and thick ink, is suitable for above 45 gsm non woven fabric printing. More high-quality printing. The machine adopts vertical type design, it save you more room compare with the traditional horizontal type screen printing machine. It have two printing units, can printing non woven fabric automatically. Each unit have independent computer control, can separately using for single color printing. Reduce the lose of one printing unit can’t running status.

Product Parameter

Item

Specification

Max printing size

1200x1100 mm

Non woven fabric roll width

1250 mm

Non woven fabric thickness

45-100 gsm

Max diameter of roller

800 mm

Printing speed

1500-2100 m/h

Power supply

380V 3P4N

Total power

55KW

Rated power

30KW

Overall size

L 9500 * W 7500 * H 2300mm

Weight of Machine

7000 KGS (40HQ*2)

Chromatic Printing Precision

1 mm

Main Features

1. Automatic feeding printing, drying and collecting. Save labors and overcome restraints caused by weather conditions.

2. With Balanced pressure, with high ink thickness. Suitable for printing on high-quality non-woven products.

3. Applied to various sized of printing screen frames.

4. Big-size printing area to print multiply layouts. Improve work efficiency.

5. Before and after full page printing, effective space between images can be reduced to minimum 1 cm.

6. High precision of printing controlled by servo motor.

7. Support non woven bag making more automatically and greatly improve work efficiency.

Printing Samples

Process Flow

Auto non woven roll feeding-> Screen Printing -> Drying -> Screen Printing -> Drying-> Position Correct Device -> Rewinding.

|

|

The following is OUR load container forNWF1400 II Two Color Roll To Roll Non Woven Fabric Screen Printing Machine. Special data would be supply after confirm your order.

|

|

|

Container

|

One 40'ft container

|

|

Weight |

7000KG |

|

Packaging Details

|

Pearl cotton with plastic film.Good suggestion for you wooden pallet, it protect the goods from the strain of long sea voyage. |

Allwell Machinery, as a professional manufacturer of spunbonded PP non woven fabric line, non woven bag making machine, non woven printing machine, soft handle sealing machine and relevantequipment, has an area of 13,000 square meters and 130 on-the-job employees.

We start from a smart factory since 2006. We keep innovating and upgrading equipment to make non woven bag more attractive and durables. 2012-2013, we innovated the first set of one time forming laminated non woven box bag making machine all of the world and get successfully market. The products and services now cover more than 80 countries.

Today, we are adhearing energy saving, efficient, environmental idea to be the leader of non woven bag making industry. We have a great dream and responsibility to provide solution for the intelligent bag making industry.

Allwell have gained the certificate of ISO9001 quality management system with all products gained the European CE.

Our R&D Team merges the advanced philosophy to practice and succeeds in applying to the related products. The excellent quality and performance of our product originatedfrom our long-term and continuous test and improvement. 2012-2013, we setup a new project of one time forming non woven box bag making machine. We succeed developed this machine - Leader Machine and get the invention patents as shown above.

2015, we succeed build a new factory and 2016 we import 5 set CNC 5 sides work coordinate machining, 24 hours processing to guarantee the precision of the machine. All our products are better than therelevant industry standards.

Pre-Sales One-stop Service

* Inquiry and consulting support

* Latest industry trends

* More fit bag making solution

* Sample testing support

* View our Factory

* Suggest layout support

After-Sales Service

* One year warranty

* Machine test video before delivery

* English Manual, Electric Diagram

* Training how to install the machine, training how to use the machine

* Engineers available to service machinery overseas

- Packing project conserlor

- Contact Name: Emy Tung

- E-mail: inquiry@allwell-group.com

- Mobile Phone: +8613567711278

- WeChat: 13567711278

- WhatsApp: +8613567711278

-135842.jpg)